90 Degree Belt Conveyor or Curve Conveyor

The 90 Degree Belt Conveyor or Curve Conveyor, that are not easily manufactured by all conveyor manufactures because, Compared to a straight line conveyor belt machine, the belt curved conveyor is a much harder machine to fabricate, with technical requirements not necessary for single direction conveyors . Belt curve conveyors require a level of experience and expertise which we have in spades.

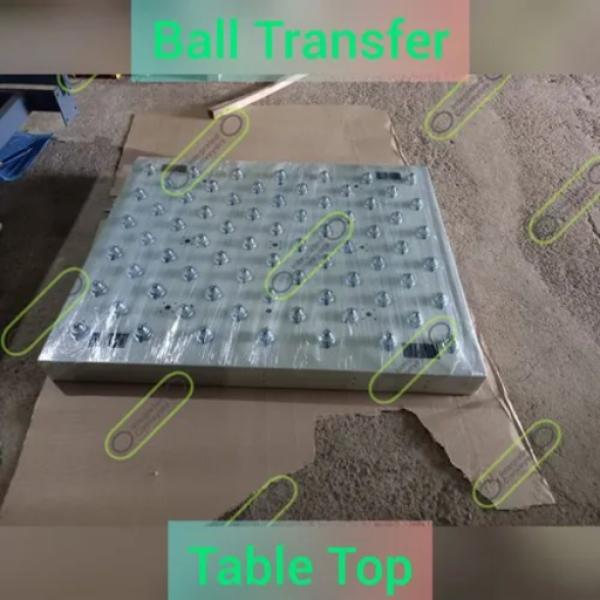

Bends are very difficult to manufacture for polyurethane and PVC belts, but are a lot easier if plastic modular. The majority of conveyor companies buy them off the shelf as it is more cost effective than to manufacture in-house, but this of course prevents a bespoke solution. The hardest aspect of manufacturing a belt curved conveyor is to prevent the outer edge of the belt from flipping over. This is achieved by attaching wheels/bearings to the outer edge of the belt, then trapping the wheels so that they cannot move from the track path. This process can be seen – and understood – more clearly in the image.

Our machines are typically built from stainless steel or mild steel, with the belts either PVC or polyurethane. They can be any size or width required. That’s the beauty of Integrated Conveyors, in-house conveyor solutions.

The curve belt conveyor is a very useful component of the complete conveyor system, allowing businesses to both efficiently utilise the available floorspace available to them, and to fulfil the necessary requirements of their own unique manufacturing, processing, packaging and distribution processes. The 90 degree curve belt conveyor offers the freedom and control that businesses need to get the maximum out of their conveyor systems.

The versatility of belt curve conveyors is such that it is employed throughout a wide and diverse range of industries and sectors. You’ll find the 90 degree belt curved conveyor in industries as diverse as laundry conveyance, warehousing, logistics and distribution, food manufacturing and processing, automotive manufacturing, general production and assembly, and parcel and packing.

The beauty of the 90 degree belt curved conveyor is its ability to be utilised in sequence with other curve belt conveyors. Two of these conveyors together can create a 180 degree bend, sending the direction of the conveyor system back on itself in the opposite direction. This is especially useful for getting the most out of limited floor-space. Alternatively, two 90 degree belt curved conveyors can produce a kink, or chicane, allowing the conveyor system to negotiate physical impediments, such as pillars, or other machinery and conveyor belt lines. The combination of curved belt conveyors will even create a complete circle if necessary. This configuration is useful for split-level conveyor lines. In truth, the curved conveyor allows for an infinite variety of conveyor line layouts, each bespoke to the individual customer’s needs.

Keywords

conveyor lines

two 90 degree belt

conveyor companies

conveyor belt lines

curve belt conveyors

belt curve conveyors

conveyor manufactures

90 Degree Belt Conveyor

complete conveyor system

line conveyor belt machine

single direction conveyors

available floorspace available

negotiate physical impediments

90 degree curve belt conveyor offers